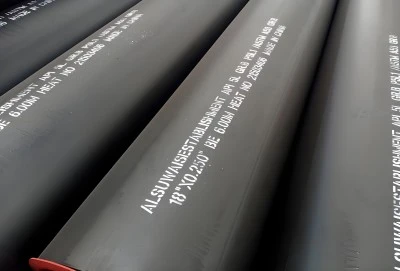

In the ever-evolving world of energy infrastructure, the importance of robust and dependable pipelines cannot be overstated. At the heart of these critical systems lies a crucial component: API line pipe. As a cornerstone of the oil and gas industry, API line pipe plays a pivotal role in ensuring the safe and efficient transportation of valuable resources across vast distances. In this comprehensive guide, we'll delve into the intricacies of API line pipe, exploring its significance, applications, and the factors that make it indispensable in modern pipeline projects.

|

|

|

Understanding API Standards for Line Pipe:

The American Petroleum Institute (API) has established rigorous standards that govern the manufacturing and quality control of line pipe used in the oil and gas industry. These standards, particularly API 5L, serve as the benchmark for line pipe production worldwide. API 5L specifications encompass a wide range of parameters, including material composition, dimensional tolerances, mechanical properties, and testing requirements.

API line pipe is categorized into various grades, each denoted by a specific letter and number combination. For instance, X60, X70, and X80 are common grades that indicate the minimum yield strength of the steel used in the pipe's construction. The higher the number, the greater the strength of the pipe, allowing for increased pressure resistance and improved performance in demanding environments.

One of the key aspects of API standards is the emphasis on consistency and reliability. Manufacturers must adhere to strict quality control measures throughout the production process, ensuring that each pipe meets or exceeds the specified requirements. This rigorous approach results in line pipe that can withstand the harsh conditions often encountered in oil and gas transportation, including high pressures, extreme temperatures, and corrosive environments.

API line pipe also undergoes extensive testing to verify its compliance with the standards. These tests include hydrostatic pressure tests, tensile strength evaluations, and non-destructive examinations such as ultrasonic testing. By subjecting the pipe to these comprehensive assessments, manufacturers can guarantee the integrity and reliability of their products, providing peace of mind to pipeline operators and stakeholders.

Choosing the Right API Line Pipe for Your Project:

Selecting the appropriate API line pipe for a specific project requires careful consideration of various factors. The choice of pipe can significantly impact the overall performance, longevity, and safety of the pipeline system. Here are some key considerations to keep in mind when choosing API line pipe:

- Operating Pressure: The maximum operating pressure of the pipeline is a critical factor in determining the required pipe grade and wall thickness. Higher pressures necessitate stronger pipe grades and thicker walls to ensure safe operation.

- Environmental Conditions: The surrounding environment plays a crucial role in pipe selection. Factors such as soil composition, temperature fluctuations, and potential exposure to corrosive substances must be taken into account to choose the most suitable pipe material and coating.

- Transportation Requirements: The type of fluid or gas being transported through the pipeline can influence the choice of pipe. Some substances may require special coatings or alloy compositions to prevent corrosion or material degradation.

- Terrain and Installation Method: The geographical features of the pipeline route and the chosen installation method (e.g., trenching, horizontal directional drilling) can impact the selection of pipe properties such as flexibility and impact resistance.

- Regulatory Compliance: Local, national, and international regulations may dictate specific requirements for pipeline construction, including the type and grade of line pipe that must be used.

- Cost Considerations: While it's crucial to prioritize safety and performance, budget constraints must also be factored into the decision-making process. Balancing the initial cost of the pipe with its long-term durability and maintenance requirements is essential for project success.

Collaborating with experienced engineers and pipeline specialists can help ensure that the most appropriate API line pipe is selected for your specific project needs. At Hebei Longma Group Limited, our team of experts is well-versed in the intricacies of API line pipe selection and can provide valuable guidance throughout the decision-making process.

Innovative Applications of API Line Pipe in Energy:

The versatility and reliability of API line pipe have led to its adoption in a wide range of innovative applications within the energy sector. As the industry continues to evolve and expand, API line pipe is finding new roles in cutting-edge projects and technologies. Here are some notable applications that showcase the adaptability and importance of API line pipe:

1. Offshore Oil and Gas Production

API line pipe plays a crucial role in offshore drilling and production operations. The harsh marine environment, combined with the extreme pressures encountered in deep-sea operations, demands pipe that can withstand these challenging conditions. High-grade API line pipe, often with specialized coatings and cathodic protection systems, is used to construct subsea pipelines that transport oil and gas from offshore platforms to onshore processing facilities.

2. Carbon Capture and Storage (CCS)

As the world focuses on reducing greenhouse gas emissions, carbon capture and storage technologies are gaining prominence. API line pipe is essential in CCS projects, serving as the conduit for transporting captured carbon dioxide from industrial sources to underground storage sites. The pipe used in these applications must be resistant to the corrosive effects of CO2 and capable of withstanding the high pressures involved in the injection process.

3. Hydrogen Transportation

With the growing interest in hydrogen as a clean energy carrier, the need for reliable hydrogen transportation infrastructure is increasing. API line pipe is being adapted for use in hydrogen pipelines, with special attention paid to material selection and welding techniques to prevent hydrogen embrittlement and ensure safe, long-term operation.

4. Geothermal Energy Systems

Geothermal power plants rely on API line pipe to transport hot water or steam from underground reservoirs to surface-level turbines. The pipe used in these applications must withstand high temperatures and potentially corrosive geothermal fluids, making high-grade API line pipe with appropriate coatings an ideal choice.

5. Enhanced Oil Recovery (EOR)

API line pipe is crucial in EOR operations, where water, gas, or chemicals are injected into oil reservoirs to increase production. The pipe used in these applications must be resistant to the various substances used in EOR processes while maintaining its structural integrity under high pressures.

6. Long-Distance Water Transportation

While primarily associated with the oil and gas industry, API line pipe is also finding applications in large-scale water transportation projects. Its durability and reliability make it suitable for constructing pipelines that move water across vast distances, helping to address water scarcity issues in arid regions.

These innovative applications demonstrate the ongoing relevance and adaptability of API line pipe in the face of changing energy landscapes and environmental priorities. As new technologies emerge and existing processes are refined, API line pipe will continue to play a vital role in ensuring the safe and efficient transportation of valuable resources.

7. The Future of API Line Pipe

As the energy industry continues to evolve, so too does the technology behind API line pipe. Manufacturers are constantly pushing the boundaries of materials science and manufacturing techniques to produce pipe that is stronger, more durable, and better suited to the challenges of modern energy production and transportation.

One area of ongoing development is the creation of high-strength steels that allow for thinner pipe walls without compromising on pressure resistance. These advanced materials can significantly reduce the weight of pipelines, making transportation and installation more cost-effective while maintaining the necessary performance characteristics.

Another focus is on improving the corrosion resistance of API line pipe. New coating technologies and material compositions are being developed to extend the lifespan of pipelines in corrosive environments, reducing maintenance costs and improving overall system reliability.

The integration of smart technologies into API line pipe is also an emerging trend. Embedded sensors and monitoring systems can provide real-time data on pipeline conditions, allowing operators to detect potential issues before they become critical problems. This proactive approach to maintenance can significantly enhance the safety and efficiency of pipeline operations.

As the world transitions towards cleaner energy sources, API line pipe will play a crucial role in enabling the transportation of alternative fuels and supporting the infrastructure needed for renewable energy projects. Adapting API standards and manufacturing processes to meet these new challenges will be essential for the continued relevance of line pipe in the energy sector.

Longma Group:

API line pipe stands as a testament to the engineering prowess and innovation that drives the energy industry forward. Its ability to withstand extreme pressures, resist corrosion, and reliably transport vital resources across vast distances makes it an indispensable component of modern energy infrastructure.

From traditional oil and gas pipelines to cutting-edge applications in carbon capture and hydrogen transportation, API line pipe continues to evolve and adapt to meet the changing needs of the energy sector. As we look towards a future of cleaner, more sustainable energy production, the role of API line pipe in enabling this transition cannot be overstated.

At Hebei Longma Group Limited, we are committed to staying at the forefront of API line pipe manufacturing, continuously improving our products to meet the demanding requirements of modern energy projects. Our extensive experience and state-of-the-art production facilities allow us to deliver high-quality API line pipe that meets and exceeds industry standards.

If you're embarking on a pipeline project or seeking to upgrade your existing infrastructure, our team of experts is here to help you choose the right API line pipe for your specific needs. Contact us today at info@longma-group.com to discuss how we can contribute to the success of your next project.