API 5L X70 pipes are high-strength steel pipes widely used in oil and gas transmission pipelines. Monitoring stress levels in these pipes is crucial for ensuring safe operations and preventing failures. This comprehensive guide explores various methods to detect when API 5L X70 pipes exceed their allowable stress limits. One of the primary methods for stress monitoring is the use of strain gauges. These devices are carefully attached to the surface of the product at strategic locations. They can accurately measure the minute deformations that occur as a result of stress. By continuously or periodically recording these strain values, engineers can calculate the stress levels within the pipe. Another approach involves ultrasonic testing techniques. Ultrasonic waves are sent through the pipe material, and the way they propagate and reflect can provide valuable information about the internal stress state.

|

|

|

Strain Gauges:

Strain gauges represent one of the most direct and reliable methods for monitoring stress in API 5L X70 pipes. These sensitive electronic devices measure the local deformation of the pipe material, which directly correlates to the stress experienced at that location. When properly installed on the pipe surface, strain gauges can provide continuous, real-time measurements of both static and dynamic strains. The working principle involves measuring changes in electrical resistance that occur when the gauge deforms along with the pipe surface. Modern strain gauge systems typically employ a Wheatstone bridge circuit configuration to achieve high measurement accuracy. For API 5L X70 pipe, which has a specified minimum yield strength of 70,000 psi (483 MPa), strain gauges can be strategically placed at high-stress locations such as bends, joints, and areas with suspected stress concentration.

Data acquisition systems connected to strain gauges can continuously log measurements and trigger alarms when strains approach critical levels. The allowable strain limit for API 5L X70 is typically set at 90% of the yield strain to maintain a safety margin. Operators can configure automated monitoring systems to alert maintenance teams when strain levels exceed predetermined thresholds.

Acoustic Emission Testing (AET):

Acoustic Emission Testing offers a powerful method for detecting stress-induced phenomena in API 5L X70 pipes. This technique captures and analyzes the high-frequency sound waves generated when a material undergoes stress-related changes such as crack formation, plastic deformation, or structural deterioration. AET sensors, typically piezoelectric transducers, are mounted on the pipe surface at strategic intervals. These sensors detect elastic waves produced by the release of strain energy within the material. Advanced signal processing algorithms analyze the captured acoustic signatures to identify and characterize different types of defects or stress-related events.

For API 5L X70 pipe, AET is particularly valuable because it can detect active damage mechanisms before they lead to failure. The method can identify micro-crack formation, which often occurs when local stresses exceed allowable limits. Real-time monitoring systems can track acoustic emission activity patterns and alert operators when abnormal stress conditions are detected.

Ultrasonic Testing (UT):

Ultrasonic Testing provides detailed insights into the internal condition of API 5L X70 pipes through non-destructive means. This method uses high-frequency sound waves, typically in the range of 1-10 MHz, to detect internal flaws, measure wall thickness, and identify areas of stress concentration. Modern UT equipment employs multiple transducers and advanced signal processing to create detailed maps of pipe conditions. Time-of-flight diffraction (TOFD) and phased array ultrasonic testing (PAUT) techniques offer enhanced capabilities for detecting stress-related damage. Regular UT inspections can track changes in wall thickness over time, which may indicate areas experiencing excessive stress.

For API 5L X70 pipes, ultrasonic measurements can identify locations where material properties have changed due to stress exposure. Areas showing significant wall thinning or unusual acoustic properties often correlate with regions experiencing higher than allowable stress levels. Automated ultrasonic testing systems can scan large pipe sections efficiently, creating detailed inspection records for trend analysis.

Hydrostatic testing remains a fundamental method for verifying the structural integrity of API 5L X70 pipe. This test involves pressurizing the pipe with water to levels above normal operating pressure, typically 1.25 to 1.5 times the maximum allowable operating pressure (MAOP). The test pressure is carefully calculated based on the pipe's design specifications and material properties. During hydrostatic testing, the pipe is monitored for pressure drops, visible deformation, or leakage. Modern testing procedures often incorporate strain measurements and acoustic monitoring to gather additional data about the pipe's response to pressure loading. This comprehensive approach helps identify potential weak points or areas where stress levels might exceed allowable limits during normal operation.

For existing API 5L X70 pipelines, periodic hydrostatic testing may be required by regulations or recommended based on risk assessment. The test results provide valuable information about the pipe's ability to withstand pressure-induced stresses and help verify that stress levels remain within acceptable limits throughout the system.

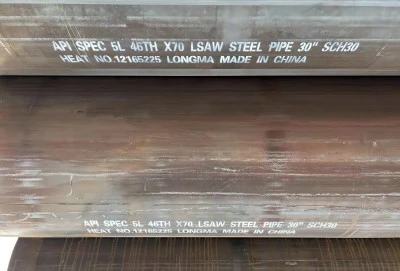

LONGMA GROUP—— API 5L X70 Pipe Manufacturer:

LONGMA GROUP specializes in manufacturing API 5L X70 pipes that meet rigorous industry standards. Their products are available in both PSL1 and PSL2 specifications, ensuring compliance with different application requirements. The company maintains strict quality control processes to ensure its pipes consistently meet allowable stress specifications. Our technical experts are always on standby to provide you with professional consultation, including proper installation guidance and maintenance advice for the API 5L X70 pipes, ensuring their long-term and stable operation in your projects.

Each pipe undergoes comprehensive testing during production to verify mechanical properties and structural integrity. LONGMA GROUP's quality assurance program includes regular material testing, dimensional checks, and non-destructive examination to ensure their API 5L X70 pipes maintain reliable performance under specified stress conditions. If you are choosing your api 5l x70 pipe manufacturers, welcome to contact us at info@longma-group.com.