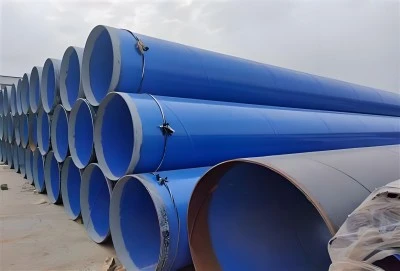

In the ever-evolving world of industrial infrastructure, the demand for durable, corrosion-resistant materials continues to grow. Among the most versatile and reliable solutions are epoxy coated carbon steel pipes. These pipes have revolutionized various sectors, offering unparalleled protection against harsh environments and extending the lifespan of crucial systems. Let's explore the top five industries that have reaped significant benefits from incorporating epoxy coated carbon steel pipes into their operations.

|

|

|

Epoxy Coated Pipes in Oil and Gas Industry

The oil and gas industry operates in some of the most challenging environments on Earth. From offshore platforms battling saltwater corrosion to onshore pipelines exposed to diverse soil conditions, the need for robust and long-lasting piping solutions is paramount. Epoxy coated carbon steel pipes have emerged as a game-changer in this sector, offering exceptional resistance to corrosion, abrasion, and chemical attack.

These pipes are particularly valuable in:

- Offshore drilling operations

- Onshore oil and gas transportation

- Refinery processes

- Storage facilities

The epoxy coating acts as a barrier, preventing direct contact between the steel and corrosive substances. This significantly extends the lifespan of the pipes, reducing maintenance costs and minimizing the risk of leaks or failures. In an industry where downtime can result in substantial financial losses, the reliability of epoxy coated pipes is invaluable.

Moreover, the smooth internal surface of epoxy coated pipes reduces friction, allowing for more efficient fluid flow. This can lead to energy savings in pumping operations, further enhancing the cost-effectiveness of these pipes in oil and gas applications.

Why Epoxy Coated Pipes Are Ideal for Water Treatment Plants

Water treatment facilities face unique challenges when it comes to piping systems. The constant exposure to chemicals, varying pH levels, and potential microbial growth can quickly degrade conventional piping materials. Epoxy coated carbon steel pipes offer a superior solution for water treatment plants, ensuring the integrity of the water supply and the longevity of the infrastructure.

Key benefits in water treatment applications include:

- Resistance to chlorine and other disinfectants

- Prevention of scale buildup

- Inhibition of bacterial growth

- Maintenance of water quality

The epoxy coating creates a smooth, non-porous surface that resists the adherence of minerals and microorganisms. This not only maintains the efficiency of the water treatment process but also reduces the frequency of cleaning and maintenance operations. The result is a more reliable and cost-effective water treatment system that can serve communities for decades.

Furthermore, the use of epoxy coated steel pipes in water treatment facilities aligns with increasingly stringent environmental regulations. These pipes help prevent the leaching of metals into the water supply, ensuring that treated water meets or exceeds quality standards.

Epoxy Coated Carbon Steel Pipes in the Construction Sector

The construction industry has embraced epoxy coated carbon steel pipes for their versatility and durability in various applications. From high-rise buildings to underground utilities, these pipes offer architects and engineers a reliable solution for both structural and functional needs.

Applications in construction include:

- Fire protection systems

- HVAC piping

- Drainage systems

- Structural supports

In fire protection systems, epoxy coated pipes resist corrosion from standing water, ensuring the system remains functional in emergencies. For HVAC applications, the smooth interior of these pipes enhances energy efficiency by reducing pressure drops and improving flow characteristics.

The durability of epoxy coated pipes is particularly valuable in underground applications, where soil conditions can be highly corrosive. By using these pipes for drainage and utility systems, construction projects can achieve longer service life and reduced maintenance requirements.

Additionally, the aesthetic appeal of epoxy coated pipes allows for exposed installations in modern architectural designs. The ability to customize the coating color provides architects with greater design flexibility while maintaining the structural integrity of the piping system.

Chemical Processing Industry: A Perfect Match for Epoxy Coated Pipes

The chemical processing industry deals with a wide array of corrosive substances and extreme conditions that can rapidly deteriorate conventional piping materials. Epoxy coated carbon steel pipes have proven to be an excellent solution, offering superior chemical resistance and longevity in these demanding environments.

Key advantages in chemical processing include:

- Resistance to a broad spectrum of chemicals

- Ability to withstand high temperatures

- Prevention of product contamination

- Extended equipment lifespan

The epoxy coating acts as a barrier between aggressive chemicals and the steel substrate, preventing corrosion and extending the life of the piping system. This is particularly important in processes involving acids, alkalis, and other reactive substances that would quickly degrade uncoated steel.

Moreover, the smooth surface of epoxy coated pipes reduces the risk of product buildup and contamination, which is crucial in maintaining the purity of chemical products. The ease of cleaning and sterilization further enhances the suitability of these pipes for pharmaceutical and food-grade chemical processing.

The ability of epoxy coated pipes to withstand high temperatures makes them ideal for processes involving heated chemicals or steam. This versatility allows chemical manufacturers to streamline their operations and reduce the complexity of their piping systems.

Mining Industry: Tackling Abrasion with Epoxy Coated Pipes

The mining industry presents some of the most challenging conditions for piping systems. Abrasive slurries, corrosive chemicals, and high-pressure operations can quickly wear down conventional pipes. Epoxy coated carbon steel pipes have emerged as a robust solution, capable of withstanding these harsh conditions while maintaining operational efficiency.

Benefits in mining applications include:

- Exceptional resistance to abrasion

- Protection against corrosive mine water

- Improved flow characteristics for slurry transport

- Reduced maintenance and replacement costs

The epoxy coating provides a hard, smooth surface that resists wear from abrasive particles in slurries. This significantly extends the lifespan of pipes used in mineral processing and tailings transport. The reduction in wear also means less contamination of the transported materials, which can be crucial in maintaining product quality.

In underground mining operations, epoxy coated steel pipes offer excellent protection against the corrosive effects of mine water. This is particularly important in dewatering systems, where pipe failure can lead to flooding and costly production delays.

The smooth interior of epoxy coated pipes also improves the flow of slurries, reducing energy consumption in pumping operations. This can lead to significant cost savings in large-scale mining operations, where efficiency is paramount.

Conclusion: The Versatility of Epoxy Coated Carbon Steel Pipes

Epoxy coated carbon steel pipes have proven their worth across a diverse range of industries, from oil and gas to mining. Their ability to withstand corrosion, abrasion, and chemical attack while maintaining structural integrity makes them an invaluable asset in modern industrial applications.

The benefits of these pipes extend beyond mere durability. They offer improved efficiency, reduced maintenance costs, and enhanced safety across various sectors. As industries continue to seek ways to optimize their operations and reduce environmental impact, epoxy coated carbon steel pipes will undoubtedly play an increasingly important role.

For businesses looking to upgrade their piping systems or embark on new projects, considering epoxy coated carbon steel pipes could be a game-changing decision. The long-term benefits in terms of reliability, efficiency, and cost-effectiveness make them a smart choice for forward-thinking companies.

To learn more about how epoxy coated carbon steel pipes can benefit your specific industry or project, don't hesitate to reach out to the experts at Hebei Longma Group Limited. Our team is ready to provide you with tailored solutions that meet your unique needs. Contact us today to explore the possibilities and take the first step towards a more resilient and efficient piping system.